What You Should Know Before Buying a Forklift Battery:

A Practical Guide for Smart Buyers -forklift battery guide

Forklifts are important tools in warehouses, factories, and logistics centers. The battery is the key part of every electric forklift. Choosing the right battery isn’t just about price — it’s about performance, reliability, and long-term value.

In this article, we will guide you on what to know before buying a forklift battery. This way, you can make a smart choice and avoid expensive mistakes.

1. Know the Type of Battery You Need

Three main forklift battery types are available:

- Lead Acid Forklift Batteries

- Many people widely use these traditional batteries because of their lower upfront cost. However, they require regular maintenance, including checking electrolyte levels and preventing acid spills.

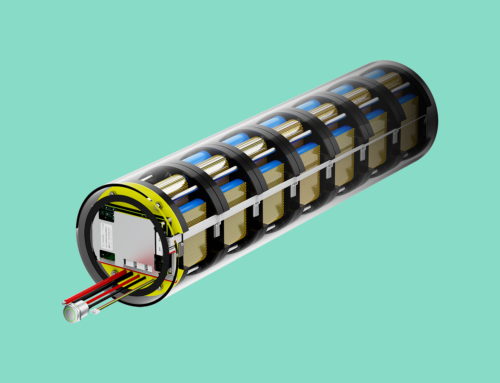

- Lithium Ion Forklift Batteries (especially Lithium Iron Phosphate / LiFePO₄)

- These batteries are modern and need no maintenance. They last longer, charge faster, and use energy more efficiently. This makes them great for companies that run multiple shifts and want to reduce downtime.

- AGM/Gel Batteries

- Sealed lead-acid batteries need less maintenance than flooded lead-acid batteries. However, they still do not perform as well as lithium batteries.

2. Match the Voltage and Battery Capacity to Your Forklift

Your forklift will require a specific voltage and capacity:

- Voltage: Common voltages include 24V, 36V, 48V, and 80V, depending on the model.

- Battery Capacity (Ah): Determines how long the forklift can operate before requiring a recharge.

- Physical Dimensions: The battery required must fit perfectly in your forklift’s compartment.

Using the wrong industrial battery can damage the forklift or reduce its efficiency.

3. Charging and Battery Charger Compatibility

Not all battery chargers are created equal. When choosing a forklift battery, consider:

- Whether your current battery charger is compatible with lithium batteries.

- If you’ll need to invest in smart charging stations.

- How we manage battery charges throughout the day.

Opportunity charging — briefly charging during breaks — is especially effective with lithium-ion forklift batteries, helping reduce downtime in forklift operating environments with tight schedules.

4. Maintenance Requirements

Different battery chemistries require different levels of care:

- Lead-acid batteries need regular watering, cleaning, and monitoring of electrolyte levels. Charge in ventilated areas to avoid gas buildup and prevent acid spills.

- Manufacturers seal lithium iron phosphate batteries and design them to be maintenance-free, incorporating integrated BMS systems that monitor temperature, voltage, and safety.

To reduce interruptions to your electric forklift batteries during operations, lithium is a smart choice.

5. Lifespan, Cost, and ROI

Here’s a comparison of life spans and total cost:

Battery TypeAverage Life SpanMaintenanceTotal Cost (5 Years)Lead-Acid1,000–1,500 cyclesHighHigh (because of labor + downtime)Lithium Iron Phosphate3,000–5,000+ cyclesLowLower (high initial, but fewer replacements)

While lead acid forklift batteries may seem cheaper at first, lithium-ion forklift batteries provide better value over time. This is especially true for businesses that operate multiple shifts.

6. Environmental and Safety Considerations

- Lithium batteries are cleaner, with no emissions or acid spills, and are fully recyclable.

- Lead-acid batteries are hazardous, and improper handling of acid can pose serious safety risks.

If your company values workplace safety or sustainability, lithium iron phosphate is the right direction.

7. Partner with a Reliable Industrial Battery Manufacturer

Choosing a supplier is just as important as choosing the battery itself. Look for a company that offers:

- Custom solutions based on your forklift operating needs

- Battery testing and data sheets

- Support for charging stations and battery chargers

- Certifications like UL, CE, and UN38.3

- Strong after-sales service and warranty coverage

At LiTech Power, we specialize in high-performance industrial batteries for forklifts and electric vehicles. If you are upgrading to lithium batteries or replacing old lead–acid forklift batteries, we can help. We will help you find the best solution.

Final Thoughts

Buying a forklift battery is a long-term investment. – Understand your equipment needs. Planning to buy a forklift battery? This guide covers everything you need to know — from battery types to lifespan, maintenance, charging, and total cost of ownership.

– Know your battery options.

– Set up your charging properly.

– Be aware of maintenance requirements.

– This knowledge helps you make a better and more cost-effective choice.

Need help choosing the right forklift battery for your fleet?

👉 Contact LiTech Power to explore our customized battery solutions and expert recommendations.

Leave A Comment