What Is a Busbar in Battery Systems?

What Is a Busbar in Battery Systems?

In modern battery systems, especially in lithium-ion battery modules and battery packs, efficient electrical connections are critical for performance, safety, and reliability. One key component that plays a central role in this process is the busbar.

This article explains what a busbar is. It also describes how it works in battery systems. Finally, it discusses why it is important for high-performance energy storage.

Understanding Busbars in Battery Systems

A busbar is a solid strip or bar that conducts electricity. Manufacturers usually make it of copper or aluminum. People use busbars to distribute and collect electrical current.

In battery systems, engineers use busbars to connect multiple battery cells together in series or parallel configurations.

Simply put:

A battery busbar enables efficient current flow between cells while minimizing electrical resistance and energy loss.

The Role of Busbar in Battery Systems

1. Electrical Connection Between Cells

Busbars link battery cells to create a battery module or pack. This pack has the needed voltage and ampere hour (Ah) rating.

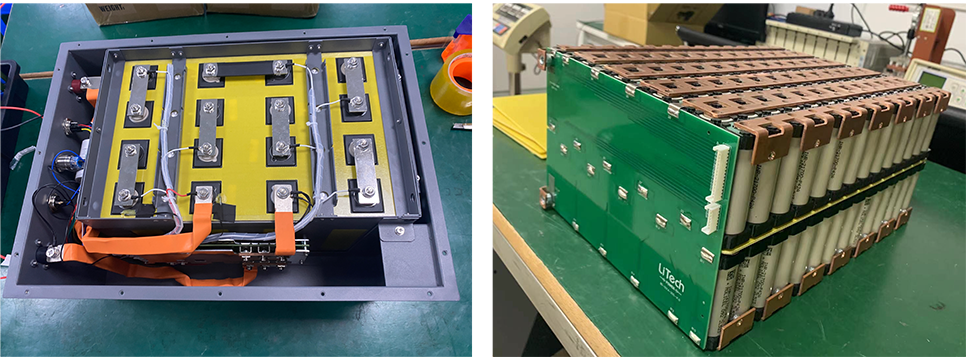

They replace traditional wiring, offering a more compact and reliable solution. Busbar in Battery System.

2. High Current Carrying Capability

Battery systems for high power uses, Busbar in Battery System, such as energy storage and power stations, require specific parts. These parts must be able to handle large currents.

Busbars are ideal for this purpose because their:

- Low electrical resistance

- Ability to carry high currents safely

- Reduced voltage drop

3. Improved Battery Performance

By reducing resistance and heat generation, busbars help improve overall battery performance and system efficiency.

Power transfer loses less energy, which means that more usable energy becomes available for generating or consuming power.

4. Enhanced Safety and Reliability

A well-designed busbar:

- Minimizes overheating

- Supports stable current distribution

- Improves mechanical stability inside the battery pack

In many designs, busbars are integrated with insulation layers, fuses, or BMS connections to further enhance safety.

Common Materials Used for Battery Busbars – Busbar in Battery System

| Material | Characteristics | Typical Applications |

|---|---|---|

| Copper Busbar | Excellent conductivity, low resistance | EV batteries, ESS, high-power systems |

| Aluminum Busbar | Lightweight, cost-effective | Large-scale energy storage |

| Nickel-Plated Copper | Corrosion-resistant, durable | Lithium battery modules |

| Laminated Busbar | Insulated, compact, safe | Battery packs and power stations |

Busbars and Battery Energy Parameters

A busbar does not decide how much energy a battery stores. However, it affects how well that energy delivers.

Key related parameters include:

- Ampere Hour (Ah): Busbars help ensure the battery can safely deliver its rated capacity.

- Power Rating: Proper busbar design supports higher power output without excessive heat.

- Energy Consumption: Low-resistance busbars reduce energy consumed during operation.

- Storage Capacity Efficiency: Efficient connections allow better use of the battery’s storage capacity.

All measurements follow the International System of Units (SI), ensuring Standard Compliance across battery designs.

Applications of Busbar in Battery Systems

🔋 Lithium-Ion Battery Modules

Used to connect cylindrical, prismatic, or pouch cells using welding or bolted connections.

⚡ Energy Storage Systems (ESS)

Support high-voltage and high-current operation in residential, commercial, and industrial energy storage.

🚀 Power Stations and Backup Power Systems

Enable fast energy transfer and stable performance under heavy load conditions.

Key Design Considerations for Battery Busbars

When designing or selecting a busbar for battery applications, engineers consider:

- Cross-sectional area (current capacity)

- Material selection (copper vs aluminum)

- Surface treatment (nickel or tin plating)

- Connection method (laser welding, ultrasonic welding, bolted joints)

- Thermal management

- Insulation and safety clearances

Conclusion

A busbar is a critical component in battery systems, ensuring efficient current distribution, reduced energy loss, and reliable performance.

A good busbar improves lithium-ion batteries. It also enhances energy storage systems and power stations. This leads to better efficiency, safety, and longevity.